High-Q Ceramic Resonator Filters for GNSS Applications

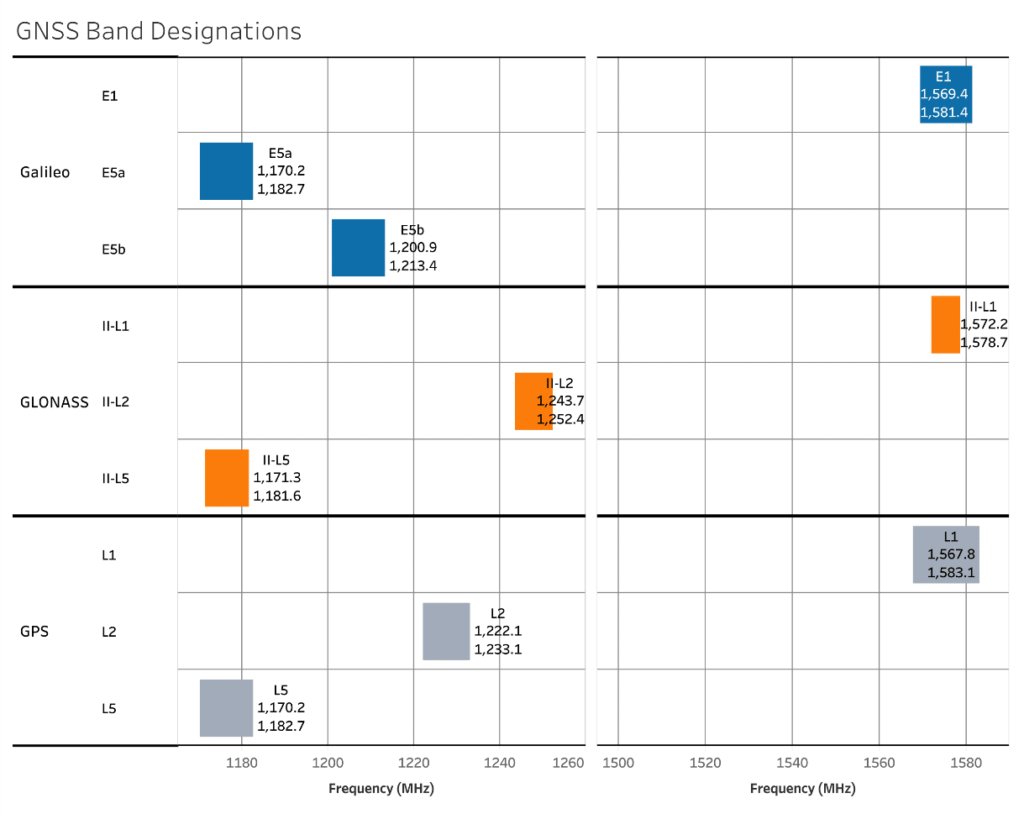

GNSS (Global Navigation Satellite Systems) has become an increasingly prevalent RF application for both military and consumer use. Early GNSS technology, or location-based services (LBS), was developed exclusively for military use and operated with a margin of error of about 10-yards (9.14m), which was sufficient at the time, but limited its suitability for end uses requiring a higher degree of precision. In the time since the first launch of GPS more than 40 years ago, the evolution of the technology has improved precision to the order of 2-3 yards (1.83-2.74m). This advancement of the technology combined with significant miniaturization and cost reduction of LBS-enabled devices has opened up a large and growing commercial market for GNSS services. For example, GNSS is now used in the agricultural market to calculate statistics for weather, soil conditions, and crop health to help farmers maximize their yields and profits. Such innovations have stimulated demand for components that support military, industrial and consumer applications.

Understanding Lumped Element Filters

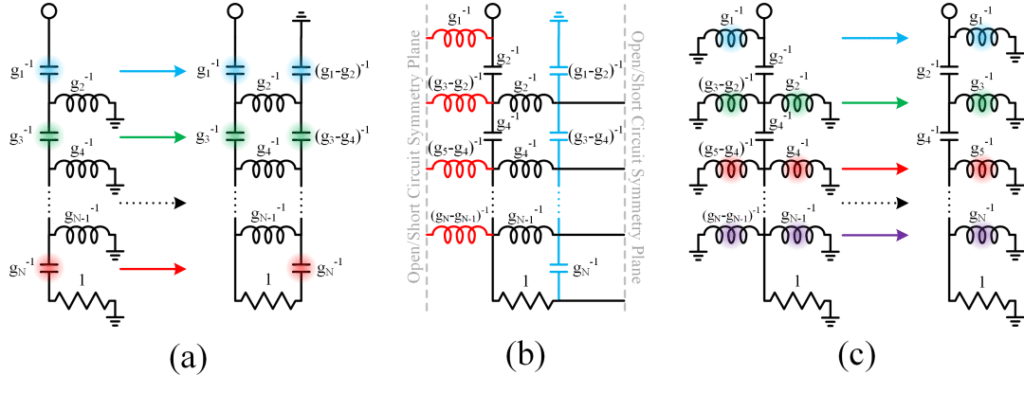

Before discussing filter designs and differentiating any given filter topology from another, it’s important to review the fundamentals of filter structures and their function. A filter is a two-port, passive, reciprocal device that allows frequencies within a given band to pass through while blocking signals outside the desired band.

There are many filter types available to the system design engineer including RLC filters, active RC filters, crystal filters, cavity filters, ceramic resonator filters and SIW, SAW and BAW filters. Filters may be fabricated using lumped elements, thin and thick film microstrip and stripline, LTCC and other manufacturing technologies. This article will focus on lumped element filters.

Impedance Matching Devices

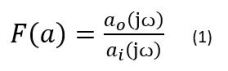

The impedance of a component or transmission line is a major concern when designing RF/microwave systems. At the circuit level, optimum performance is obtained when devices are matched to the desired system impedance, typically 50Ω or 75Ω. At the system level, each building block must be matched to the system impedance to maintain performance along the signal path.

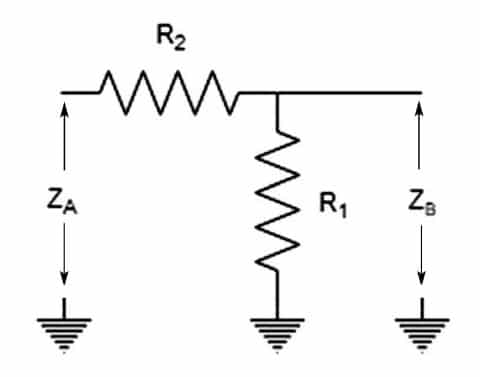

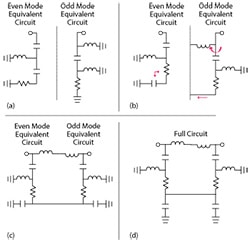

Reflectionless Filter Basics: A Brief History of the Genesis of Reflectionless Filters

The advent of broad bandwidth amplifiers, analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and software-defined radios has brought about growing interest in broadband communications, radar, and sensing applications. For these applications, there is often a need to preserve the highest sensitivity and dynamic range possible within the receiver signal chain and to mitigate the number and strength of harmonics and spurious content in the transmitter signal chain. This is a substantial challenge considering the nature of non-linear components within these circuits, namely compression-mode amplifiers, mixers, multipliers, and frequency-conversion electronics.

Renewing Our Founding Values as a 50-Year-Old Startup

The Mini-Circuits story is well known to many in the RF and Microwave industry. Some know us for our advertising, some know us as one of the first companies to transform the pricing structure of RF components, and some know us through the personal relationships they had with Harvey Kaylie, our founder and chief executive for the first 50 years of our history.

FILTERING WITHOUT REFLECTIONS: Flattening Multiplier Chain Conversion Efficiency & More

A new class of filter, which exhibits broadband matched impedance at its ports, has recently been invented and made available. This new device, the reflectionless filter, has demonstrated a variety of benefits when used to replace conventional filters in a signal chain. This white paper briefly introduces the reflectionless filter and compares conventional filter and reflectionless filter behavior. Use cases are presented examining how reflectionless filters can improve system performance when used with mixers, ADCs, and receiver signal chains. Lastly, an experiment is described and test results presented to compare the conversion loss ripple in multiplier chains when reflectionless and reflective filters are used to filter spurious signals.

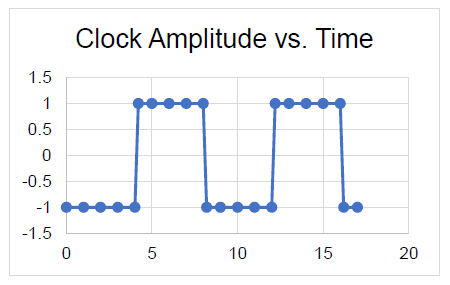

Specifying VCOs for Clock Timing Circuits | Application Note

Timing is everything for many systems, especially for modern electronic systems with high-speed data converters and high-resolution sampling. A clock source is “the keeper of time” in these systems and system timing performance is very much dependent upon the performance of its clock source. For some system designers, a clock source automatically means a crystal oscillator, typically a single-frequency source. But some system designers, especially those faced with synchronizing systems at multiple clock frequencies, have learned to appreciate the flexibility of using voltage-controlled oscillators (VCOs) as clock sources.

Reflectionless Filters Improve Linearity and Dynamic Range in Microwave Systems

Filters are fundamental building blocks of nearly every modern RF/microwave system used to eliminate unwanted signals in receiver and transmitter architectures. Until recently, study and research in practical filter design has been largely devoted to topologies in which rejection of stop band frequencies is accomplished by reflecting undesired signals back to the source. Meanwhile, there are many applications in which these reflections produce intermodulation products, gain ripples, and other problems in system performance. For example, non-linear devices such as mixers, multipliers and high-gain amplifiers which respond to out-of-band frequencies are highly sensitive to the reflections caused by conventional filter designs. This becomes especially challenging as filters are often needed near or adjacent to active devices in the signal path to better define bandwidth or suppress unwanted harmonics.

Bridging the Gap between the University and the RF Industry

With 5G standards barely off the drawing board and headlines filled with speculation about all the related capabilities, what sometimes gets lost in the buzz is that these technologies will depend heavily on a new generation of RF engineers to develop the circuits and systems to realize the dream. It is difficult to conceive of the number of new products that will incorporate high-speed, wideband RF communication once next generation wireless networks are rolled out, and the industry needs a deep pool of technical talent to support the demand.

An Interview with Mini-Circuits Founder and CEO, Harvey Kaylie

Q: Defense and military applications have always been a crucial segment of the global market for RF and microwave products. How do you see the defense market evolving in 2018 and beyond as compared to recent years?