Achieving First-Spin Success in LTCC Components with Advanced Material Simulation Models

By Aaron Vaisman, Ben Kahtan and Camilo Gomez-Duarte, Mini-Circuits LTCC Design Group

Introduction

Since the advent of Network Synthesis Theory at the turn of the last century, filter designers have been developing ever more sophisticated solutions to translate polynomial transfer functions into working, physical components.

The body of knowledge for lumped components is well established in the famous “Big Red Filter Bible,” Microwave Filters, Impedance Matching Networks, and Coupling Structures, by Matthaei, Young and Jones, and for distributed components in James Hong’s Microwave Filters for RF/Microwave Applications. This knowledge combined with the advent of advanced software tools for filter synthesis and the commercialization of computerized full field solution algorithms such as the Method of Moments (MoM) and the Finite Element Method (FEM) have given designers a powerful toolkit to realize both known and arbitrary topologies.

Even given the maturity of the theory and state of the art in filter synthesis and simulation software, simulation results are still generally taken with a measure of caution. One of the most significant design challenges remains achieving agreement between simulation and working design in a timely fashion. Depending on the technology being used, it’s not unusual for designers to cycle through multiple design and manufacturing spins before results meet the desired performance. This adds substantial time and cost to the design cycle, and directly affects time to revenue. Setting up a truly accurate simulation requires capturing every physical parameter that may affect real-world filter performance. Designers need to consider a daunting variety of factors. Some questions that must be considered include:

- Has the simulation model been parameterized such that the real world variables related to the physical implementation and operating conditions are accounted for?

- What kind of interpolation should be used between frequency points?

- Does the 3D model capture the physical manifestation of a given structure?

- Is the meshing different at different frequency bands?

- Is skin depth accounted for correctly within the simulation tool for lower frequency bands?

- Is the substrate dispersive, and if so what are its dispersion curves?

- Have effective conductivity and the conductor’s surface roughness models been accounted for?

Mini-Circuits LTCC design group has spent years addressing these questions and many others. The reality of traditional simulations is that in the past, material impacts have not been well enough understood to account for all the real-world effects on performance. Therefore, a deeper understanding was necessary to eliminate superfluous manufacturing spins and meet performance requirements on the first try. By combining hundreds of different test structures, extensive material characterization and modelling, novel design workflows and home-brewed algorithms, Mini-Circuits has been able to transfer the trial and error from production runs at the fab to the simulation phase, early in the design process. These innovations have enabled us to consistently achieve first-spin success on LTCC fi lters and other components beyond 50 GHz.

This article will explore some of the specific challenges of simulating LTCC structures. The design workflow will be described and case studies provided to demonstrate first-spin fidelity between simulation and measurement. Finally, extensions will be discussed for other exploratory filter topologies at high frequencies as well as for other products and technologies.

Material Characterization and Modelling

Mini-Circuits typically combines two common simulation techniques to predict the RF performance of passive devices prior to their fabrication, each with its own pros and cons. The Method of Moments (MoM) technique works by meshing the conductive metallizations within the structure. This method is fast to perform and iterate and is useful for structures with low port count and low ratio of metallization to substrate. However, it is mostly limited to 2D surfaces and assumes substrates extend infinitely in space, so it doesn’t provide a true substrate truncated 3D model.

The Finite Element Method (FEM) of simulation provides a true 3D model that allows us to truncate volumes. This is a frequency based method that works by meshing the substrate structures rather than the conductors. FEM simulations better capture the coupling and parasitic effects through the substrate as well as the effects of truncating the 3D structure, which are absent in MoM. The drawback is that FEM simulations are typically slower to implement.

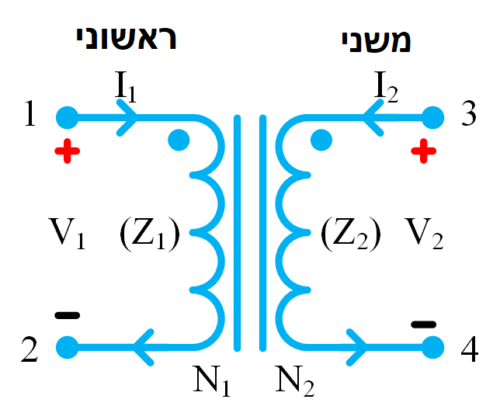

The FEM approach is more accurate for LTCC filters where the signal travels in a 3D fashion through a monolithic structure. Ideally, the characteristics of that structure would be uniform. However, in reality, LTCC structures consist of multiple layers of ceramic and conductive material with dispersive and anisotropic behavior. A true 3D characterization of the material is therefore required to account for the non-linear behavior of signals traveling through a structure with these properties.

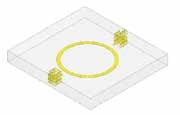

While these two approaches are powerful, in the past, they were incapable by themselves of achieving close agreement between simulation and measurement, and multiple design spins were still required. This limitation necessitated a deeper understanding of the material structure for its contributions to the real-world performance of the device. Mini-Circuits has gone through the painstaking effort of characterizing the material properties of substrates and conductive elements used in LTCC products up to the millimeter wave range. This required the use of hundreds of test structures, including single and multi-modal resonator topologies, waveguide resonators, lumped capacitor and inductor structures, among others. A proprietary algorithm was developed just to analyze the volume of test data from our measurement workflow.

Figure 1: (a) LTCC panel with test coupons. (b) Diagram of measurement setup with RF probes. (c) 3D model of ring resonator (top and bottom layers hidden). (d) Ring resonator: E-Field plot of 1st harmonic. (e) Ring resonator: E-Field plot of 7th harmonic.

After two years of intensive effort building and characterizing test coupons and then modelling the measured performance into our simulation tools across broad bandwidths, Mini-Circuits has amassed what we believe is one of the most advanced understandings of LTCC technology in the industry. Our efforts have included characterization and modelling of the material properties of all elements used not only in our LTCC product line, but also in semiconductor products and other technologies as well. We now have high confidence in our material models which, combined with our suite of design tools and novel design flow, has enabled us to achieve first spin success on component designs up to 50 GHz.

This capability is unique in the industry. It enables Mini-Circuits to develop and release standard parts to our catalog at a faster rate, which supports the needs of customers with high volume requirements, and it enables us to develop highly customized solutions for customers in more specialized applications with very fast turnaround. In all cases, it translates to lower development time and cost, and faster time to market.

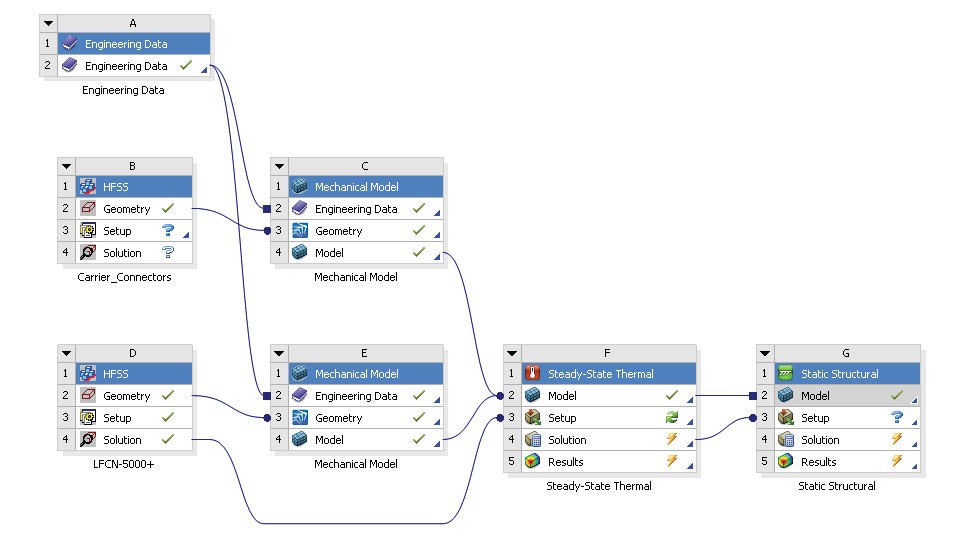

Multi-Physics Workflow

Our comprehensive material modelling combined with state-of-the-art design and simulation tools has allowed us to innovate a novel, multi-physics simulation workflow. A multi-physics simulation incorporates multiple simulators, each working within a particular domain: electromagnetic, structural and thermal. The individual simulators use each other’s results as a component of their own simulation setups. For example, electrical simulation results from HFSS® are employed to define spatially-varying heat generation in a thermal simulation in ANSYS®. The computed temperature rise is then employed in turn to compute deformation of the model geometry.

This initial simulation series often results in performance that does not meet the specified design requirements, so the effects of thermal and mechanical analysis are fed back into the MoM and FEM engines to compensate for the effects of the thermal impact. This iterative process is completed as many times as necessary to achieve the desired performance. In a traditional design cycle, a prototype would be fabricated after the first round of simulations, tested in the lab, and then redesigned and fabricated again. Our workflow moves that trial and error to the front of the design cycle, avoiding multiple rounds of fabrication and testing in the lab.

Consider for example a customer requirement for a part that can handle 4W RF input power. Traditionally, the part would be designed and an evaluation run fabricated. The parts would be soldered to eval boards and put through burn-in test. If the part then burns out at 3W, it would need to be redesigned. Because LTCC products are monolithic, it isn’t practical to find the point of failure through destructive physical analysis.

By contrast, with a multi-physics simulation workflow, we are able to accurately and reliably evaluate power handling prior to the first build of the device, saving time, cost, and no small measure of frustration.

Advantages of this workflow include:

- Greater insight into the power handling of a model under diverse operating conditions (DC, RF and transient)

- Realistic assessment and optimization of thermal impact on RF performance and reliability

- Forecasting of mechanical integrity of terminals in the presence of CTE mismatches

- Optimization of the physical structures to reduce size

Figure 3: Simulations in multi-physics workflow: (a) EM simulation mesh used to determine heat generation as an input to the thermal simulator. (b) FEM thermal/mechanical simulation mesh. (c) Thermal simulation results showing temperature distribution. (d) Mechanical stresses after physical deformation is computed from the thermal results.

Examples of Simulation vs. Measurement

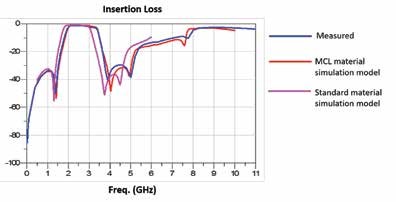

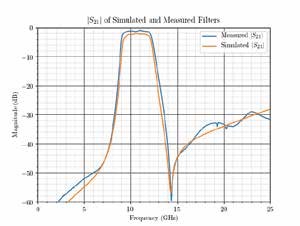

Figure 4 shows a plot of S21 for an LTCC bandpass filter from a standard simulation model, Mini-Circuits advanced material simulation model and actual measured performance. The pink plot represents the simulation results without the material knowledge we’ve modelled into newer simulations. Note the disparity between this simulation and the measured performance. The red line represents Mini-Circuits’ new simulation workflow incorporating all the material characterization and modelling we’ve conducted. Note that this simulation tracks the measured filter performance very closely across the full measured range.

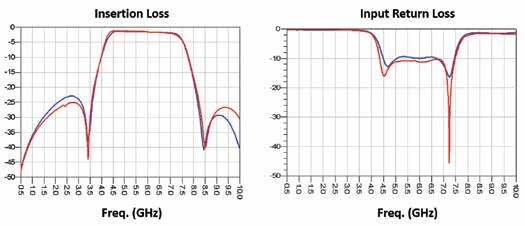

Figure 5 shows additional comparisons between Mini-Circuits’ advanced simulation results and measured performance for a different LTCC bandpass filter model. Both S21 and S11 are shown, illustrating highly accurate simulation results for both parameters. These cases are representative of the unique capability to achieve close agreement between simulation results and measured performance after the first design run from the fab.

Extensions

The learnings illustrated above were shown for LTCC filter designs utilizing lumped topologies, but they have broad applicability for exploratory filter topologies and other technologies as well.

The recent shift to applications at higher and higher frequencies has necessitated exploration of distributed filter topologies. Genesys® offers filter synthesis for some of the known distributed topologies, but doesn’t include synthesis and optimization tools for filters derived from Coupled Matrix Filter Synthesis Theory. At Mini-Circuits’ we’ve taken many of the concepts from the research literature and created our own algorithm capable of synthesizing arbitrary distributed filter topologies based on our specs. We’ve also created an optimization tool capable of producing simulated S-parameters and optimized dimensions on a full 3D model.

We have extended the material simulations used for LTCC components to other technologies in our portfolio including MMIC and stripline architectures. The same capability is also a vital element of our active effort to develop advanced packaging solutions for surface-mount components on soft substrate up to 55 GHz.

Conclusion

Single pass success has long been considered the holy grail in design workflows. The physically complex nature of LTCC technology makes it particularly challenging to achieve agreement between simulation and working design on the first try. By using extensive material characterization and modelling together with advanced design tools, proprietary algorithms and our novel design workflow, our simulations now account for real world effects on performance to the degree that we can consistently achieve first-spin success in LTCC designs. Our capabilities in this area have helped us accelerate standard and custom parts to reduce customers’ time to market and to enhance existing LTCC filter designs, reducing size and improving rejection performance.

The design capability presented in this article extends to other technologies and innovations in high-frequency packaging solutions. These extensions will be addressed in greater depth in subsequent papers.