Adapting Non-Sealed Surface Mount Parts for Hi-Rel Customer Assembly Processes

JonidXhakollari, Manufacturing Process Engineer, Mini-Circuits

The perfect integration of a product within the customer’s assembly process can be just as critical to the success of that product asthe electrical performance. Mini-Circuits and many RF/microwave component manufacturers build surface mountcomponents that are soldered onto customers’ PC boards using a reflow process. Following reflow, the board must be cleaned to remove solderballs, flux, salt deposits and other debris. While a number of cleaningmethods exist, the industry – and especially manufacturers of equipment for military and other hi-rel applications – have gravitated towards aqueous wash. A conformal coating is then applied to protect the circuit from moisture and other adverse environmental conditions. This process poses unique challenges for the integration of surface mount parts into customer assemblies, particularly components with open and semi-sealed case styles.

This article presents a proprietary technique Mini-Circuits has developed to adapt non-sealed surface mount components to preserve high reliability after aqueous wash and conformal coating in customer assembly processes.

Reliability Risks of Open and Semi-Sealed Surface mount Parts

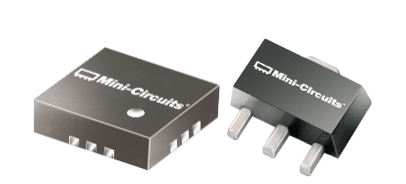

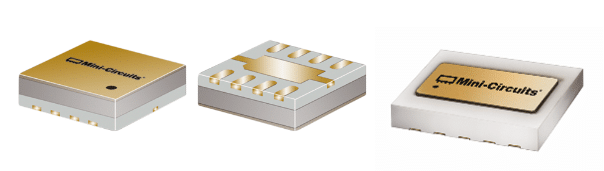

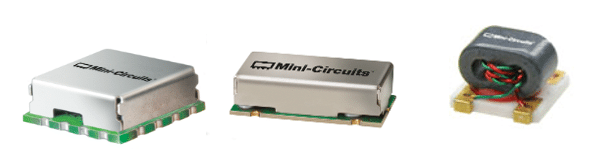

Mini-Circuits’ surface mountparts may be categorized into three basic package types:

Plastic encapsulated and hermetically sealed components are generallywell-suited to hi-rel assembly processes without any special adaptations. Open and semi-sealed components, however, are susceptible to performance shifts and even catastrophic failurewhen exposed to the conditions of aqueous wash and conformal coating processes. During aqueous wash, components are exposed to de-ionized water and PCB cleaning agents at high pressure and temperature which can ingress into the unit package and become trapped. After aqueous wash, moisturealong with any contaminants trapped inside the caseof semi-sealed units can lead to dendritic growth, shorting, corrosion and a variety of other known reliability risks.

Open component assemblies are less problematicthan semi-sealed assemblieswith respect to trapped moisture, but for some more sensitive open structures such as filters and diplexers, the customer’s conformal coating can change the dielectric properties of the circuit, resulting in shifts in RF performance. For example, mixers and limiters are generally unaffected by contact with conformal coating, whereas VCOs and diplexers are sensitive and unsuitable for conformal coating unless contained in a sealed case.

The Solution: Proprietary Sealing Method

In an ideal world, we would simply adopt hermetically sealed cavity packaging for everything to withstand customers’ assembly processes, but there are practical limits to this solution. Hermetic packaging addssignificant cost to the component, and it is highly impractical to make hermetically sealed packages for larger structures. Therefore an alternative technique to adapt open and semi-sealed surface mount components for hi-rel assembly without adding extraneous cost or technical inconvenience to theprocess is highly desirable.

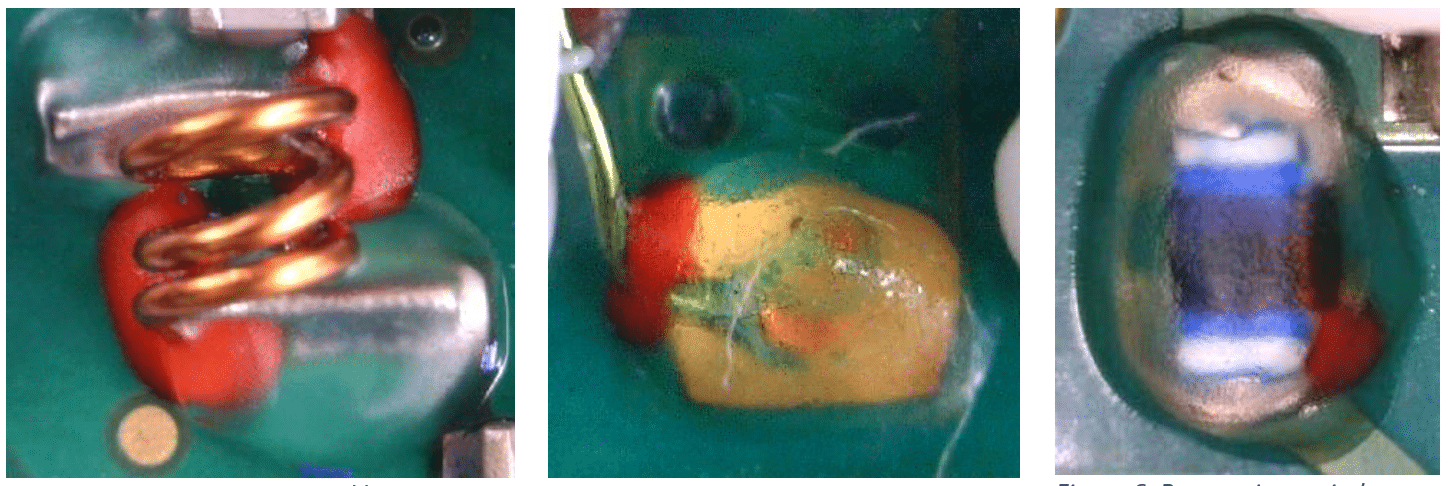

In response to customer requirements for open and semi-sealed components in our catalog for systems undergoing hi-rel assembly processes, Mini-Circuits developed a proprietary sealing method to protect these components during the aqueous wash process and enable them to operate reliably within the customerconformal coating. A specialpre-coatingis applied tocertain areas ofthe Mini-Circuits unit, which prevents direct contact of the cleaning solution and the customer’s conformal coating with the unit’ssensitivecircuitry.This pre-coating has been qualified to withstand the conditions of customer reflow, aqueous wash, andconformal coatingprocesses without failures or shifts in RF performance.

Figure 4: Pre-coating on air coil legs. Figure 5: Pre-coating on weld spot. Figure 6: Pre-coating on inductor.

The pre-coating seals thesensitive areasof the unitsuch that during the customer’s reflow process, there is no wicking of solder or creation of solder balls in the sealed structure, which would otherwise cause reliability problems. This economical technique can be used to adapt open or semi-sealed surface mount components in Mini-Circuits’ catalog to preservereliabilityin hi-rel assembly processesfor minimal increase in cost.

Conclusion:

The trend toward aqueous wash and conformal coating in hi-rel applications means components that were once universally usedwill be increasingly unsuitable for integration into customer assembly processes in their standard form. Fortunately, Mini-Circuits has now developed a cost-effective approach to adapt non-sealed surface mount components for outstanding reliability in customer assembly processes involving aqueous wash and conformal coating. This gives customers the freedom to select components without limitations based on case style. Open and semi-sealed parts may be adapted for customers utilizing aqueous wash and conformal coating without adding inordinate cost or complexity to theirboard designor assembly process.