The first type of RF cable is the coaxial cable. Coaxial cables are made up of an inner conductor, an outer conductor, and a dielectric material in between. These cables are known for their ability to maintain a consistent impedance throughout the cable, which helps to minimize signal loss. Coaxial cables are commonly used in applications where a consistent impedance is required, such as in wireless communication systems.

A flexible RF cable is a type of RF cable that is designed to be flexible and easy to bend. These cables are commonly used in applications where the cable needs to be bent or moved frequently, such as in portable equipment.

A semi-rigid RF cable is a type of RF cable that is designed to be stiffer than a flexible cable, but still able to be bent to some degree. These cables are commonly used in applications where the cable needs to be bent occasionally, such as in test and measurement equipment.

A rigid RF cable is a type of RF cable that is designed to be stiff and not able to be bent. These cables are commonly used in applications where the cable does not need to be bent, such as in fixed installations.

An armored test cable is a type of coaxial cable used in RF (Radio Frequency) test and measurement applications where durability and shielding are critical. It is designed to provide a high level of shielding against electromagnetic interference (EMI) and other sources of signal degradation, while also being able to withstand harsh environmental conditions. The cable is typically constructed with an inner conductor, dielectric insulator, outer conductor (shield), and an outer jacket made of a rugged, durable material such as polyurethane. The outer shield may be composed of a braided wire mesh or a spiral-wound strip of metal to provide additional protection against EMI. The armored construction of the cable allows it to withstand bending, crushing, and other types of mechanical stress, making it suitable for use in field or laboratory test environments. RF armored test cables are available in a variety of lengths and connector types to suit different testing applications.

A flexible interconnect cable is a type of coaxial cable designed for use in applications where a high degree of flexibility is required. It is typically used to connect two components or devices within a system, where conventional rigid coaxial cables would be unsuitable due to their lack of flexibility. RF flexible interconnect cables are constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane. This construction allows the cable to bend and flex without breaking, making it ideal for use in applications where frequent movement or vibration may occur. RF flexible interconnect cables are available in a variety of lengths and connector types to suit different applications and are commonly used in RF test and measurement systems, medical equipment, and other applications where space and flexibility are at a premium.

A flexible test cable is a type of coaxial cable designed for use in RF test and measurement applications. It is typically used to connect test equipment such as signal generators, spectrum analyzers, and network analyzers to the device under test. RF flexible test cables are designed to have low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness to minimize signal loss and interference. The cable is constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane. This construction allows the cable to bend and flex without breaking, making it ideal for use in applications where frequent movement or vibration may occur. RF flexible test cables are available in a variety of lengths and connector types to suit different testing applications and are commonly used in RF test and measurement systems, aerospace, and defense applications.

A flexible test cable with booted joints is a type of coaxial cable designed for use in RF test and measurement applications where extra protection is required at the cable connectors. The booted joint is a molded, protective covering placed over the connector to provide additional durability and strain relief to the cable connection. The boot is typically made of a flexible, durable material such as silicone rubber or polyurethane. The RF flexible test cable itself is constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is also made of a flexible, durable material such as polyurethane. This construction allows the cable to bend and flex without breaking, making it ideal for use in applications where frequent movement or vibration may occur. RF flexible test cables with booted joints are available in a variety of lengths and connector types to suit different testing applications and are commonly used in RF test and measurement systems, aerospace, and defense applications.

A Hand-Flex interconnect cable is a type of coaxial cable designed for use in applications where a high degree of flexibility and ease of use is required. It is typically used to connect two components or devices within a system where conventional rigid coaxial cables would be unsuitable due to their lack of flexibility. The Hand-Flex design of the cable includes a highly flexible section at one or both ends of the cable, which allows the cable to bend and flex without breaking. This makes it ideal for use in applications where frequent movement or vibration may occur, such as portable or handheld devices.

RF Hand-Flex interconnect cables are constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane. The cable is designed to have low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness to minimize signal loss and interference.

RF Hand-Flex interconnect cables are available in a variety of lengths and connector types to suit different applications and are commonly used in RF test and measurement systems, medical equipment, and other applications where space and flexibility are at a premium.

Precision test cables are coaxial cables that are designed to provide accurate and reliable signal transmission for RF test and measurement applications. These cables are characterized by their high-quality construction, low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness.

RF precision test cables are typically constructed using high-quality materials and manufacturing processes to ensure that they meet stringent performance requirements. The cables typically feature a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane.

RF precision test cables are available in a range of lengths, connector types, and frequency ranges to suit different test and measurement applications. They are commonly used in RF test and measurement systems, aerospace and defense applications, and other applications where accuracy and reliability are critical. Some RF precision test cables are also available with specialized features such as phase matching, phase stability, and low skew to further enhance their performance.

RF Hand-Flex interconnect cables are constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane. The cable is designed to have low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness to minimize signal loss and interference.

RF Hand-Flex interconnect cables are available in a variety of lengths and connector types to suit different applications and are commonly used in RF test and measurement systems, medical equipment, and other applications where space and flexibility are at a premium.

Super flexible interconnect cables are a type of coaxial cable designed to provide a high degree of flexibility for use in applications where conventional rigid coaxial cables would be unsuitable due to their lack of flexibility. These cables are designed to bend and flex without breaking, making them ideal for use in applications where frequent movement or vibration may occur, such as in mobile or portable devices.

RF super flexible interconnect cables are typically constructed using a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane. These materials and manufacturing processes are optimized to provide both high flexibility and good RF performance, such as low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness.

RF super flexible interconnect cables are available in a variety of lengths and connector types to suit different applications and are commonly used in RF test and measurement systems, medical equipment, and other applications where space and flexibility are at a premium. Some RF super flexible interconnect cables are also available with specialized features such as phase stability, low skew, and high temperature resistance to further enhance their performance in specific applications.

Temperature stable cables are coaxial cables that are designed to maintain their electrical performance over a wide range of temperatures. These cables are characterized by their low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness, and are ideal for use in applications where accurate and reliable signal transmission is required over a wide temperature range.

RF temperature stable cables are typically constructed using high-quality materials and manufacturing processes to ensure that they maintain their performance characteristics over a range of temperatures. The cables typically feature a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a durable material such as polyurethane or Teflon.

RF temperature stable cables are available in a range of lengths, connector types, and frequency ranges to suit different applications. They are commonly used in aerospace and defense applications, as well as in RF test and measurement systems and other applications where accurate and reliable signal transmission is critical. Some RF temperature stable cables are also available with specialized features such as low skew and phase stability to further enhance their performance in specific applications.

VNA (Vector Network Analyzer) cables are specialized coaxial cables used to connect network analyzers to devices under test (DUTs) for the purpose of measuring their electrical performance. These cables are characterized by their high-quality construction, low insertion loss, low VSWR (Voltage Standing Wave Ratio), and high shielding effectiveness to ensure accurate and reliable signal transmission.

RF VNA cables are typically constructed using high-quality materials and manufacturing processes to ensure that they meet the stringent performance requirements of network analyzer measurements. The cables typically feature a flexible inner conductor, a dielectric insulator, and an outer conductor (shield) made of a braided wire mesh or a spiral-wound strip of metal. The outer jacket of the cable is made of a flexible, durable material such as polyurethane or Teflon.

RF VNA cables are available in a range of lengths, connector types, and frequency ranges to suit different network analyzer measurement applications. They are commonly used in RF test and measurement systems, as well as in research and development labs, manufacturing facilities, and other applications where accurate and reliable signal transmission is critical. Some RF VNA cables are also available with specialized features such as phase stability and low skew to further enhance their performance in specific applications.

In conclusion, RF cables are an essential component in a wide range of electronic systems. The different types of RF cables offer unique characteristics and capabilities, making them suitable for different applications. Whether you need a coaxial cable for a wireless communication system, or a twin-axial cable for a test and measurement equipment, there is an RF cable that can meet your needs. Understanding the characteristics of different types of RF cables can help you choose the right one for your application, ensuring that your system functions correctly and efficiently.

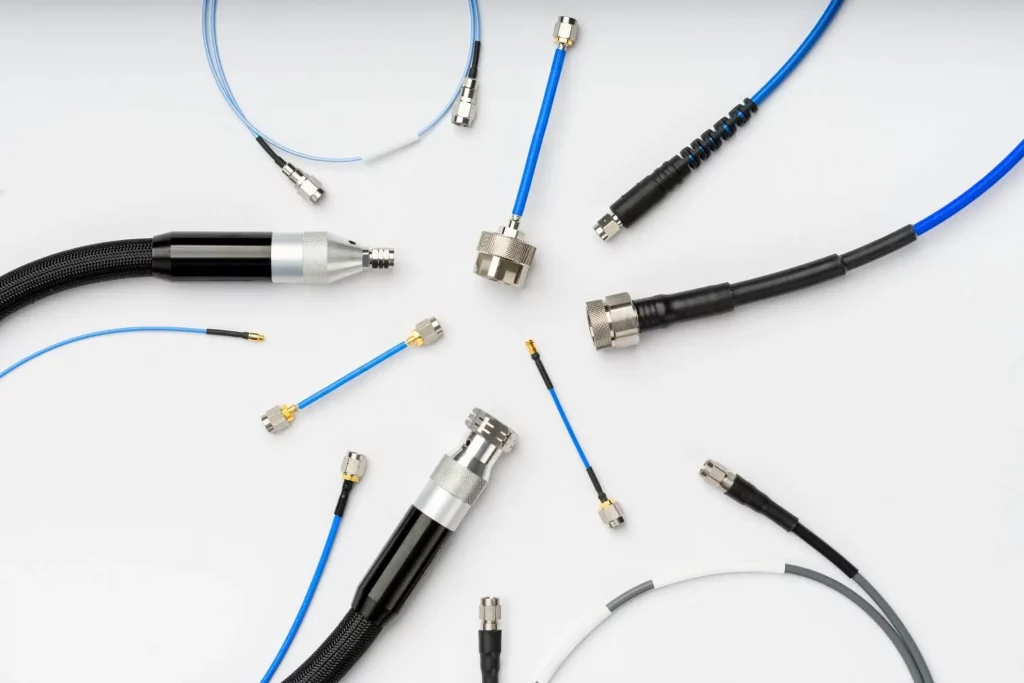

Mini-Circuits offers a wide of catalog RF Cables, including Armored Test Cable, Flexible Interconnect Cables (0.047″ center diameter, 0.086″ center diameter, 0.141″ center diameter), Flexible Test Cables, Flexible Test Cable – Booted Joints, Hand-Flex Interconnect Cables (0.047″ center diameter, 0.086″ center diameter, 0.141″ center diameter), Precision Test Cables, Precision Test Cable – Economy, Super Flexible Interconnect Cables (0.047″ center diameter), Temperature Stable Cables, VNA Cables, from DC to 67 GHz for all types of applications and mounting preferences. View the catalog: https://mcdi-ltd.com/rf-cables/

MCDI, Mini-Circuits Exclusive Representative in Israel, serves as the direct link for customers in Israel to Mini-Circuits’ world class selection of high-quality RF, IF and microwave products from DC to 100+ GHz.

Our strong partnership with Mini-Circuits and Mini-Circuits Israel, the Mini-Circuits design center in Israel, allows us to provide customers with direct access to local technical service and engineer-to-engineer application support.