Understanding Suspended Substrate Stripline Filters

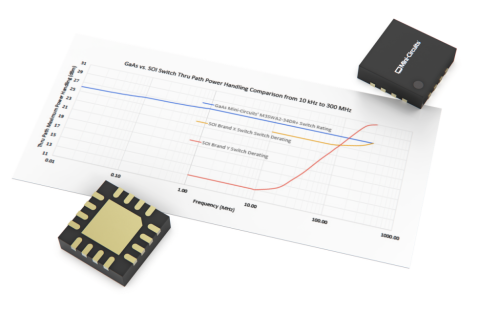

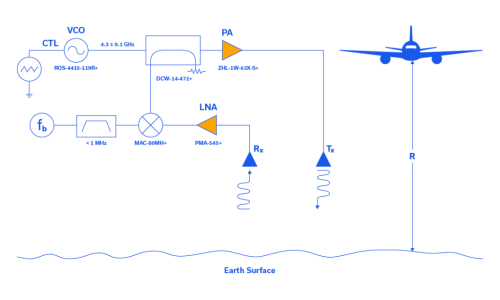

To manage signal purity in communications and test systems, no component is more important than RF filters. To meet the needs of these advanced systems, Mini-Circuits’ suspended substrate stripline filter products offer state-of-the-art performance featuring unique passband, stopband characteristics and outstanding reliability in harsh operating environments. The range of available filter types supports the needs of military, aerospace and commercial systems, including instrument systems, ultra-broadband receivers, laboratory testing, 5G and many other wideband communications systems.

Suspended Substrate vs. Traditional Stripline Construction

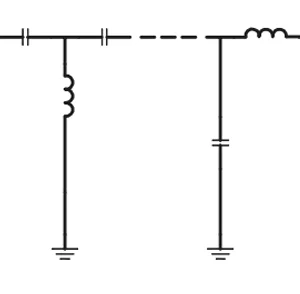

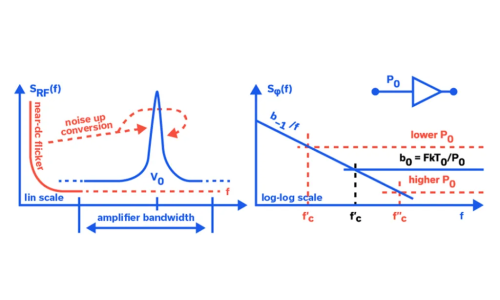

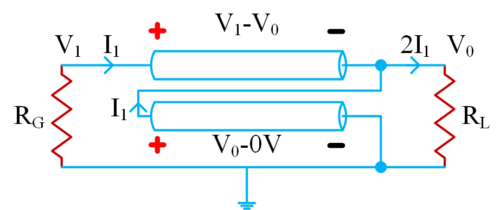

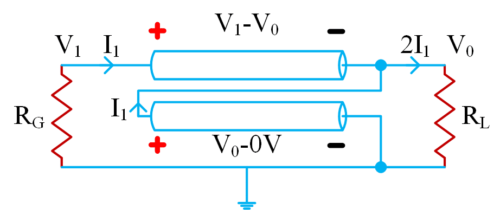

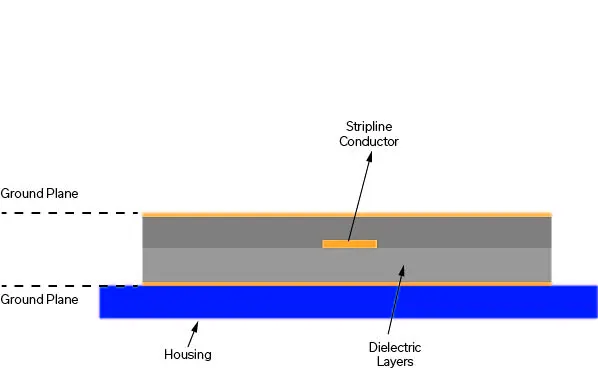

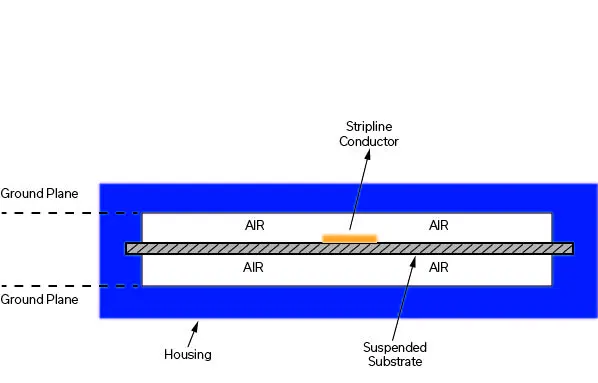

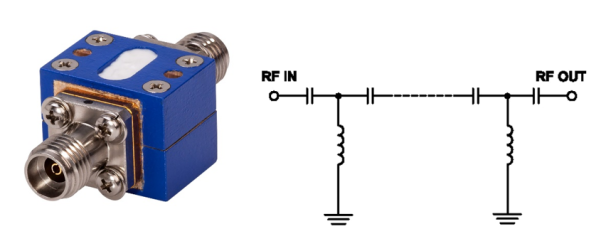

Suspended substrate stripline technology uses a printed circuit board suspended between two parallel ground planes, with air as the dielectric instead of a solid material. This technique results in very high Q factor and low loss, since most of the electric field is in air rather than a lossy dielectric material. Conventional microstrip or stripline filters (Figure 1) use common microwave substrates, typically PTFE or ceramic based materials. These materials introduce losses due to their higher dielectric constant, which is significantly greater than that of air, which approaches the ideal dielectric constant of 1.0 represented by a vacuum. Thus, the losses in suspended substrate filters (Figure 2) are limited to conductor resistance, dielectric losses in the small amount of supporting substrate material, and any high-current points in the stripline patterns.

The flexible geometry of an air dielectric design also allows a wide range of impedance values, which enables the implementation of broadband designs. The suspended PCB uses high-frequency substrates with low dielectric loss and surface roughness. This contributes to the lowest possible passband insertion loss at frequencies up to 40 GHz. This construction method also improves temperature stability.

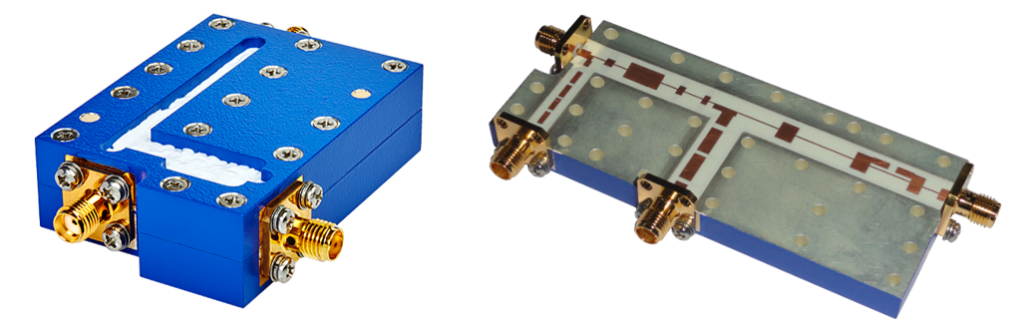

Mini-Circuits’ suspended substrate filter line covers passbands spanning DC to 40 GHz in SMA and 2.92mm connectorized housings. Products covering up to 65 GHz, using 2.4mm and 1.85mm connectorized packages are in development.

Key Performance Features

Suspended substrate filter technology is capable of achieving extremely wide passbands, greater than 8x the cutoff frequency (fc). Similarly, the stopband may also be up to 8x fc. Passband Insertion Loss is typically <1 dB. Low pass and high pass filters can be cascaded to achieve a fractional bandwidth as wide as 160%.

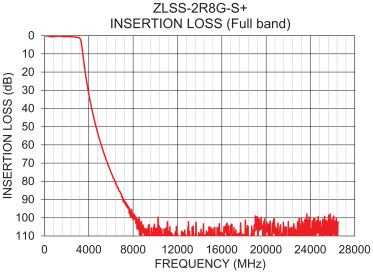

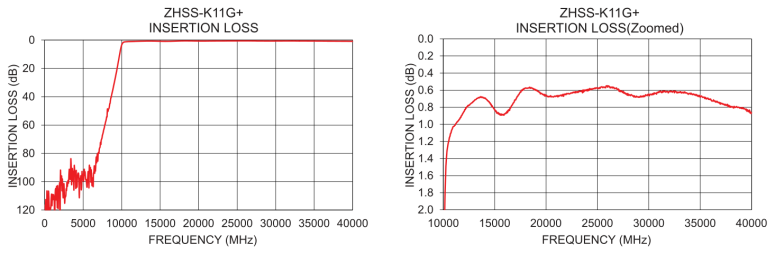

The high Q and low loss of suspended substrate designs combine to provide faster roll-off of the stopbands than other fabrication technologies, typically -30 dB within 10% of the passband edge (1 dB point). These characteristics, along with advanced filter design techniques and precision construction, achieve a stopband rejection floor of around -100 dB. An example is the frequency response plot of a lowpass filter in Figure 4 below. This unique combination of ultra-wide passband and stopband range with sharp selectivity makes suspended substrate an excellent option for wideband systems in spectral environments where fundamental or harmonic emissions from adjacent bands may interfere with the desired operating band.

Temperature stability is better in suspended substrate filters than in other printed circuit filter realizations, since the fields are mainly in air, not in a dielectric material which absorbs some of the energy and dissipates it as heat. Typical power handling for Mini-Circuits designs is up to 15 Watts with operating temperature rating from -40 to +85℃. This technology also withstands harsh environmental conditions, meeting challenging specifications for vibration and mechanical shock.

The Mini-Circuits Filter Line

Mini-Circuits’ line of suspended substrate stripline filters includes the following types:

Low pass – for rejection of undesired harmonics, spurs and interference at frequencies above fc.

High pass – for effective rejection of unwanted signals below fc.

Band pass – to block unwanted signals and interference both above and below the desired range of operation.

Diplexers – a high pass/low pass configuration that allows two signals at different frequencies to share a single path, such as a transmission line, while isolating the sources from one another.

Triplexers – Similar to the diplexer, but handling three signals, with a bandpass filter in the frequency range between the high pass and low pass sections.

Quadruplexers – Like the triplexer, but with an additional band pass section that allows signals in four frequency ranges to be combined while maintaining isolation.

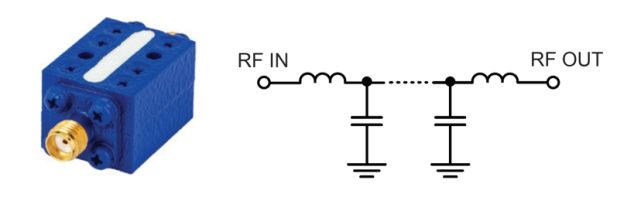

Low pass filters are currently offered with passband cutoffs from 2.8 to 24 GHz. The stopband range extends up to 40 GHz. A typical lowpass filter and a functional schematic are shown in Figure 5 below.

High pass filter products have passband cut-offs in the frequency range of 2 to 24 GHz with passbands extending to 40 GHz. One of Mini-Circuits’ high pass filter products is the ZHSS-11G-S+, shown below with its functional schematic in Figure 6 and frequency response plot in Figure 7.

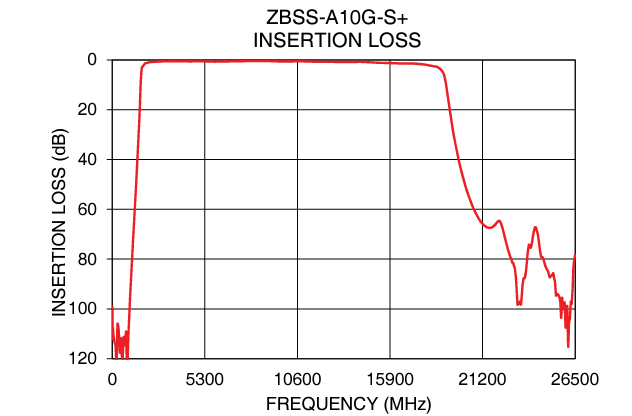

Suspended substrate band pass filters in the Mini-Circuits catalog have passbands spanning 1.6 to 18 GHz with fractional bandwidths up to 160%. Case style and simplified schematic for model ZBSS-A10G-S+ are shown in Figure 8, and its characteristic S21 response is shown in Figure 9.

Figure 8: Frequency response for ZBSS-A10G-S+ suspended substrate band pass filter.

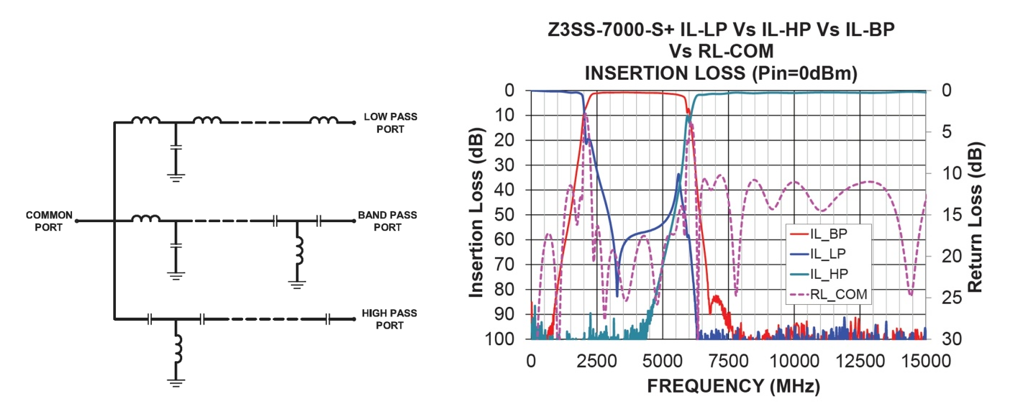

The high Q and steep passband roll-off combine to support the design of high-performance multiplexers. Low pass-high pass diplexers are offered with passbands up to 20 GHz in the high pass channels.

Triplexers add an additional band pass channel in the 1.6 to 7 GHz range. Quadruplexers may be implemented using yet another band pass channel to separate the signal stream into four ranges. Figure 10 shows the functional schematic of a Mini-Circuits triplexer, Z3SS-7000-S+ along with the frequency response plot for all three channels.

Manufacturing Challenges

Because suspended substrate is a high Q filter technology, real-world implementations are especially sensitive to the smallest variations in housing dimensions, line widths, PCB tolerances and other factors. The sharpness of the roll-off in the frequency response means that small shifts in any of these factors can result in large shifts in the filter’s passband and stopband performance. These effects become even more pronounced at high frequencies. For this reason, a high level of precision is required in the manufacturing process to achieve the desired performance and repeatability from unit to unit and lot to lot.

In addition to precision tooling and machining, sophisticated production techniques are followed with attention from knowledgeable technicians, who complete the assembly. A well-trained, experienced staff is required along with the understanding that RF performance depends directly on the assembly process. The process includes 100% visual inspection, plus a comprehensive set of measurements and quality checks to ensure each part’s mechanical, electrical, and environmental specifications.

Mini-Circuits has also developed proprietary methods to overcome performance variations and guarantee, tighter tolerances and better repeatability at production volume. This capability minimizes yield loss in production, which contributes to Mini-Circuits’ ability to offer competitive pricing in the market.

Summary

Suspended substrate stripline filter technology offers many advantages for designers looking for wide passbands, deep rejection and sharp roll-off in the transition. By utilizing air cavities instead of dielectric materials used in traditional stripline fabrications, these filters achieve better Q and better thermal stability, making them suitable for many high-performance applications in a wide range of operating conditions.

Mini-Circuits line of filters and multiplexers using suspended substrate stripline technology offer high performance solutions for wideband commercial, military and aerospace applications. Advanced design methods and precision production techniques are used to achieve the desired performance, while also maintaining high manufacturing yield and competitive pricing.