An Interview with Mini-Circuits Founder and CEO, Harvey Kaylie

Brandon Kaplan

Q: Defense and military applications have always been a crucial segment of the global market for RF and microwave products. How do you see the defense market evolving in 2018 and beyond as compared to recent years?

A: We believe that there will be continued strength in the defense and aerospace business on a global level. We are seeing a recovery of spending in Europe after many years of almost no investment on defense electronics, and a growing international market that’s complementary to what we’re seeing in the United States. As the global defense budgets expand, funding will eventually flow down to RF/microwave suppliers, and we’re already seeing new investments in applications such as long range detection radars, EW surveillance, countermeasures and communications, among others.

One of the trends we’ve noticed is that although spending in the defense market is increasing, there’s a much greater focus on cost than we’ve seen in the past. That emphasis on cost reduction is driving changes in the technology used to create integrated multi-function assemblies. We see military customers shifting from the use of MMIC die with chip-and-wire integration to the adoption of lower-cost surface mount packaging on PCB – even up to Ku Band, and there’s a desire to extend the same capability to Ka Band.

We also see military customers adopting parts qualified under commercial standards and using commercial off-the-shelf products as much as possible, which is noteworthy. The JEDEC standards for commercial semiconductor products are very similar, and sometimes even surpass the qualification and reliability testing requirements of the usual MIL standards, and I think there’s a question of how much value the incremental screening and qualification of MIL STD 883 and 38534 really add when parts have already met these stringent commercial standards. The fact that military customers are accepting JEDEC standards and can now make use of commercial technologies represents a big sea change in the way they’re doing business and in the way RF/microwave suppliers will support the defense market looking ahead.

Q: What products and technologies is Mini-Circuits currently working on that you believe will add new capabilities for defense applications?

A: We’re investing in a number of areas we believe will benefit the defense community. First, we’re moving our product line higher in frequency. In general, we believe military applications will benefit from the investments of the commercial wireless community in developing millimeter wave hardware from Ka Band through W Band. These bands were once exclusively the domain of low volume applications such as satellite communications but have now been elected by the 5G commercial wireless standard. 5G is driving new development in portions of the spectrum that overlap with existing military applications, and we believe this surge of investment and commercial development in high frequency systems will also be a windfall for defense applications.

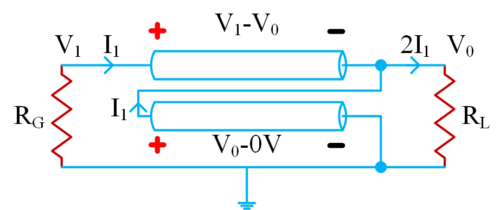

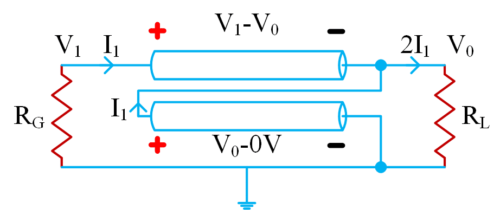

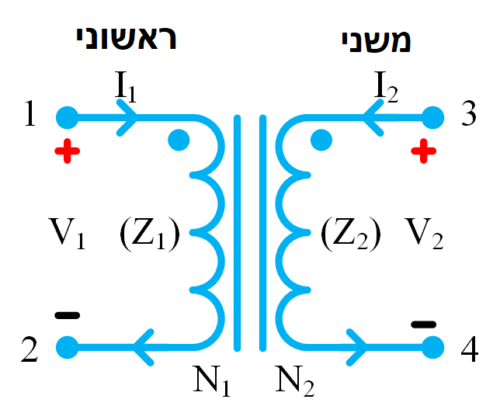

In keeping with that trend, Mini-Circuits is expanding our portfolio with a greater number and variety of coaxial products and GaAs MMIC products up to 40 and 50 GHz to support the infrastructure that will be needed in those commercial markets, but our goal is to make these products operate over very wide bandwidths so they will have dual use for military applications. Our coaxial portfolio now features splitters, adapters, attenuators, terminations, DC blocks, test cables and interconnect cables up to 40 and 50 GHz. We also recently introduced ultra-wideband MMIC mixers and multipliers up to 40 GHz, and we have a number of other MMIC products in our pipeline including switches, amplifiers, splitters and couplers.

We continue to make developments in our proprietary line of reflectionless filters. These filters have been heavily adopted in a number of defense and aerospace applications from broadband EW and ELINT applications to more narrow-band radars. The requirements for super-high dynamic range and wide frequency range typical of defense and aerospace applications make these products ideal additions to the system lineup because they suppress unwanted spurs and intermods caused by signal reflections in the RF chain. This is a capability that the industry has been trying to achieve for 40 years. Reflectionless filters are a unique, patented technology, and we’re the only game in town.

Finally, beyond new products, we’re heavily invested in the development of new packaging technologies. As previously discussed, we see a desire in the defense community to migrate from expensive chip and wire solutions to traditional surface mount integration on soft substrate up to 50 GHz. There are currently packaging options available up to 50 GHz, but these are still very costly. The market is looking for low-cost surface-mount packaging solutions with consistent, reliable performance up to 50 GHz, and our goal is to address this demand. We’re also expanding our existing hermetic, air-cavity packaging to support hi-rel applications at higher frequencies

Q: What do you believe are some of the biggest challenges defense and aerospace customers are currently facing?

A: One of the biggest challenges to military customers today is without a doubt stability in the supply chain. The RF and microwave industry in particular has gone through tremendous turnover in the last several years with a series of major consolidations triggering a surge in product obsolescence. Suppliers have matured to the point where they all have strong End-of-Life notification processes, but an EOL notice falls far short of the paradigm in the military and defense world where program lifecycles span decades, and requirements of twenty-year support lives are the norm.

This is a key area that differentiates Mini-Circuits from the typical suppliers. Over our 50 year history, we have upheld a policy of supporting our customers through the full life of their system requirements. Part of our commitment to our customers is to provide them with parts for as long as they need them. This may include finding redesign solutions when faced with EOL from one of our own suppliers or having special parts fabricated. We always extend the effort to find redesign solutions and protect the customer from any impact on his production. Our policy on product longevity makes Mini-Circuits unique in the industry, and it allows us to give our customers peace of mind in a business climate where shifts in the supply chain have become more common, and especially in the defense market where supplier stability is more critical than ever.